How long have you been at Serpa?

I think I’m approaching 24 years. My hire date was January 1999. I was 19 years old when I started here. I was out of school, not doing much. My uncle was the CNC programmer, that’s where I got a lot of my knowledge from. Everything was handed down here, none of us went to school for it, it was all learned here at Serpa back then.

What is a typical day for you here at work?

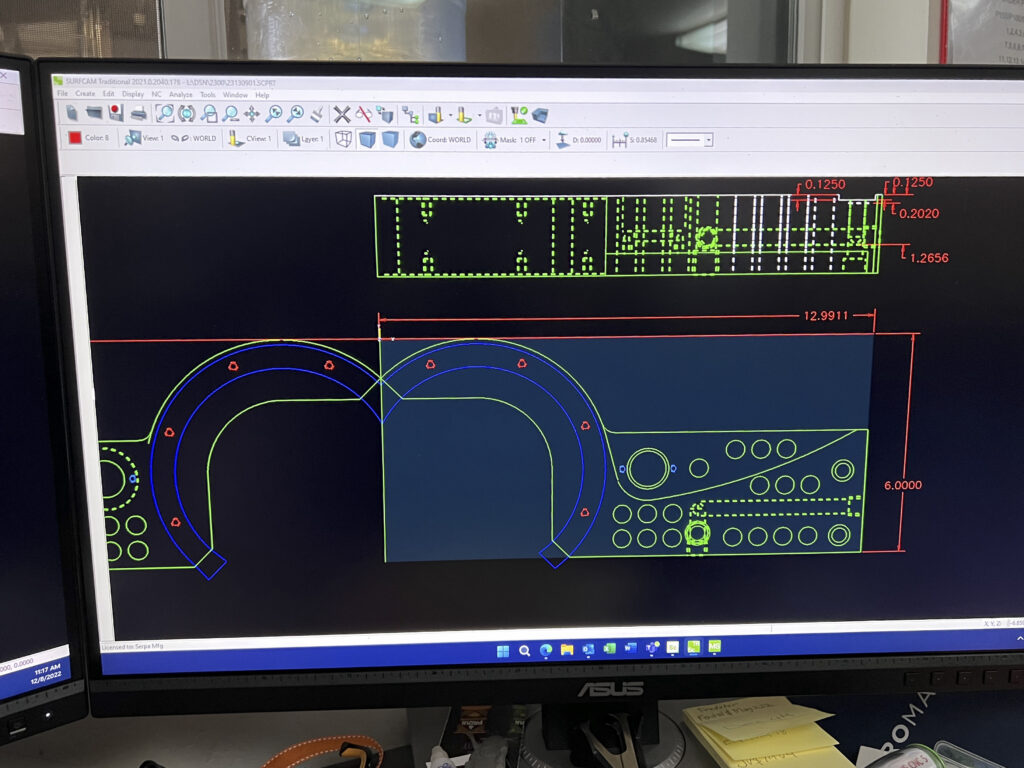

Normally I’ll come in and I’ll see if there are any pending red service prints that are due or past due, or if they’re doing FAT, I’m aware of what parts need to get to the shop and once I situate all the parts that need to get sent out, I’ll start writing the program. I save it to our ethernet, where the CNCs have the ability to download all the programs that I create so they can start machining the parts. And throughout the day if there’s anything wrong that needs to be modified or changed, I background edit the programs for them. If they run into a problem where they can’t hold the part properly, I have to figure out how to hold it so it’s safe for them, so they can machine the part. And that’ll go on until probably 11 o’clock. From then on I get to work on machines that are coming up. I don’t have any downtime.

What inspires you to succeed every day?

To see these machines actually function and run and operate. There’s never the same machine so it’s a challenge—it’s a rewarding feeling to go look at the machine that you were a part of; somebody engineered it, they drew it, and we machined it—that feeling of successfully making the part the way it was intended to work. That’s always the goal back here: to make the right part.

Because you can see the machine, you take pride in the machine; then you see them in action.

Enrique Hernandez

What is the most meaningful part of your day?

A lot of times it’s just watching the guys get along because machine shops, they have it hard, especially guys will say that they’re superior to over people. To me when I can write a program that everybody understands, to get everybody involved, and bring their self-esteem up, or their performance as well. It’s the group camaraderie that we have back there, it’s good to see that, all these guys get along as well.

When do you have the most fun at work?

You’ll never see me down; it’s hard to get me down. But to watch the guys take that pride, that initiative that they made that part—I enjoy watching them succeed and make parts that look very difficult. Some parts look difficult, but with the right program and the right personnel, all parts can be machined. I have fun the minute that I get here.

How does Serpa compare to other companies?

The opportunity that was given to me at a young age; I take that seriously. Fernando and myself considered each other good friends—it’s the loyalty I have had to him. I’ve had opportunities to go somewhere else, but I considered, is it worth leaving what I’ve built here? A lot of stuff that I have now is because I’ve been here and I don’t think this company’s ever treated me wrong. I care a lot about these guys; opportunities have been there, a lot of places, but no, that’s never even crossed my mind.

What experiences here at Serpa have you most enjoyed?

The machining, hands down—any part—from learning how to operate the mill, the lathe, and taking a raw stock of material and making a part. That’s the most rewarding thing that you can accomplish; to make something out of practically nothing.

If someone new were joining the team, what one piece of advice do you think they should know?

They have to know the sounds and the functions of the machines—that knowledge is key, that could ultimately lead to saving your fingers or your eyes. A lot of machinists are missing fingers, I’m fortunate to still have all ten.

What’s something you’ve learned?

How to manage time. There’s no downtime, but when there are FATs and the clients are here, it’s go go go. So you have to sit and manage; if somebody has an issue with a program, if you can hold them a little longer and then do what you need to do to get the clients successfully running their machines. Time management is key here.

How are Serpa machines different?

I’ve been here long enough, I’ve hired and fired a lot of machinists; one thing that always comes up is the cleanliness of our machines. We take pride—here we know what we’re making the part for, we can see the machine. I bring some of the new guys over to assembly to see where their parts go, “You can’t do this to this part, this part’s visible.” Because you can see the machine, you take pride in the machine: then you see them in action. I’ve watched the quality of our machines go probably from a Volkswagen to a Corvette. Now I don’t know how much more we can improve other than incorporate more robotics—everything’s hidden, well-driven, that’s where that pride comes in, I know where these machines came from and where they are now: 24 years later we’re still bettering the machines.